Quality Guarantee

Since its establishment in 2001, ChengGong Tools has always regarded "Quality First" as its core principle. We firmly believe that superior quality is the only way to earn customer trust and international market recognition. Therefore, we embed this philosophy into every step, from raw material procurement to final product delivery. Our commitment is clear: zero compromise on flawed output. We consistently provide durable, precise, and reliable professional-grade tools, ensuring every use reflects the value of the ChengGong brand.

Precision Raw Material Screening

Quality begins at the source. We implement 100% strict inspection of all incoming steel and alloys.

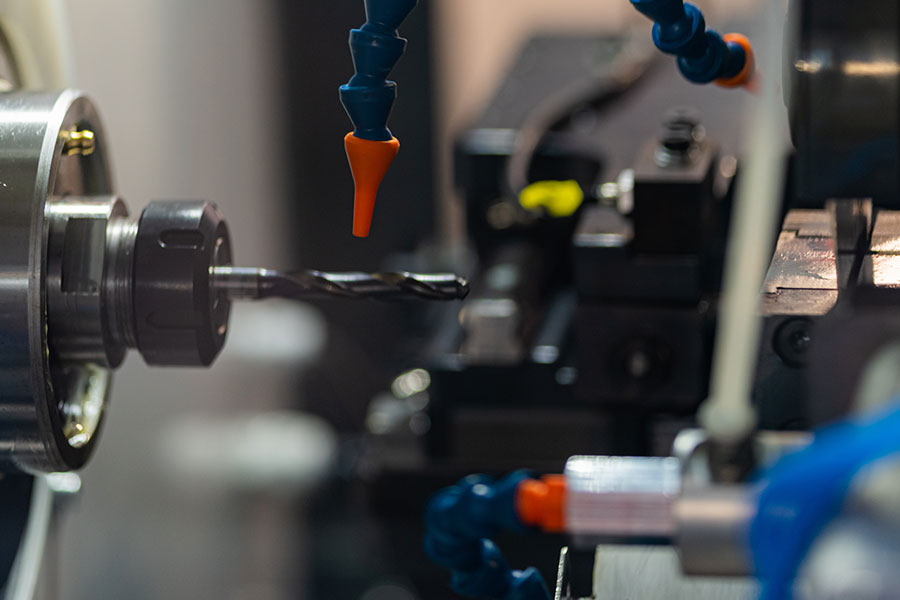

In-Process Monitoring

At key processes like CNC grinding and heat treatment, we have established multiple quality control ...

Heat Treatment Process Control

Heat treatment is the core process determining tool performance (hardness, toughness).

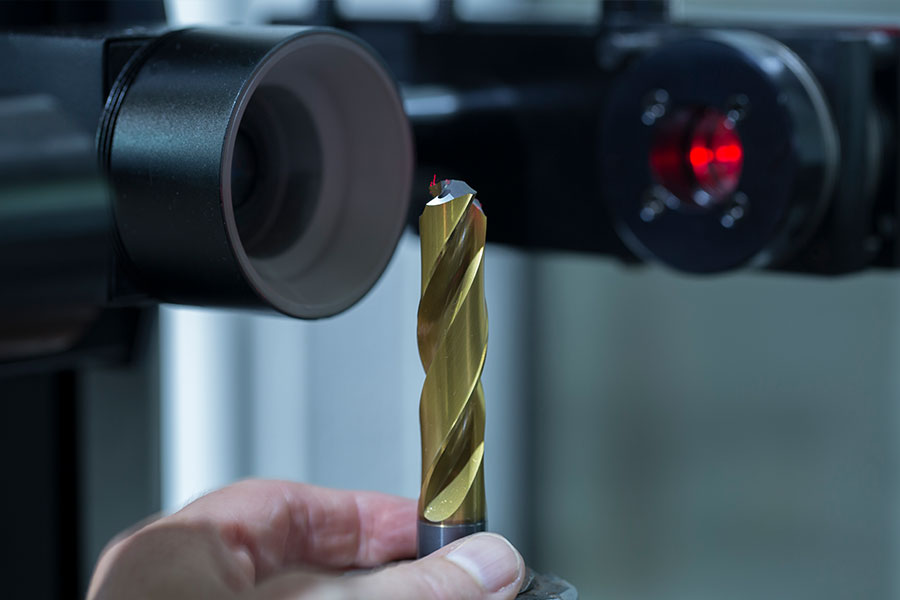

Finished Product Precision Inspection

All finished products must pass a final precision inspection.

Performance & Durability Testing

After precision checks, products undergo sampled performance tests.

Audit, Traceability & Packaging

Before packaging, all inspection data is re-audited.

Through these rigorous quality inspections, we can ensure the consistency and reliability of our products, allowing our customers to be assured and satisfied with product quality.

Continuous Improvement

Quality improvement is a never-ending journey. We are committed to fostering a culture of continuous improvement. Through systematic customer feedback collection, production data analysis, and regular internal audits, we constantly identify and optimize potential issues in our processes. Our team undergoes rigorous quality management training to ensure the system's effective operation.